Cost-benefit analysis of cooking with milk powder: Introducing the environmental cost of food processing

Present times demand being cost-conscious and hence cost-effective in all our endeavours. Milk powder is obviously costlier than equivalent milk and hence its potential as ‘milk on the shelf, in emergency’ would be questionable, especially in these times of easy and immediate availability of fluid milk. But the devil is often in the detail.

Introduction: The cost of the equipment-use and of the fossil fuels to evaporate water from milk apart from the other standard ‘overheads’ are the obvious reasons why milk powder is costlier than the equivalent amount of milk. Even otherwise, milk reconstituted from powder cannot compare with fresh fluid milk in any way. But wait; let us compare milk concentrated to ‘low-water milk’ and powder diluted to the same ‘low water milk’. The case of rabadi as ‘low water milk’ is an eye-opener and helps introduce the environmental issues which are never far away from processing of any kind – even cooking!

Consider the following self-evident and simplified ‘equations’:

(i) Milk – water (partial) + (sugar + nuts + flavor) = Rabadi.

(ii) Milk – water (less than above) + milk powder + (sugar + nuts + flavor) = Rabadi.

(iii) Milk (+ milk powder) + fuel + sugar + nuts + flavor + time and effort – water – flue gases produced by fuel and released to atmosphere = Rabadi.

(iv) Total cost = cost of ingredients + cost of fuel + environmental cost + cost of time and effort. This is obviously, simplified.

(v) Environmental cost = depletion of non-renewable fuels + addition of Greenhouse Gases to the atmosphere. Let’s understand this cost thru a comparision of petrol and diesel-driven vehicles and Electric Vehicles.

Understanding the environmental cost – the case of EV’s: An EV essentially exploits the absence of environmental pollution when fossil fuel (petrol or diesel) is not burnt in running it. It runs by channeling the electrical energy transferred to and stored in its battery at the ‘charging station’. As the vehicle runs, the battery discharges needing eventual ‘recharging’, seemingly producing no pollution. The consumable in an EV is, thus, the electrical energy.

Now the electrical power is transferred to the charging station mostly from the power plant far away where fossil fuels are burnt to generate it. (Green Energy does not use fossil fuels but it is presently a miniscule % of total power produced.) Now the EV is billed for the in-going electricity metered at the charging station and, say, consumes ‘a’ units so transferred to its battery per km. The corresponding power produced at the generating plant is a’ (a’>a, but close because of transmission and conversion losses). The fuel consumption and gaseous pollution per km will correspond to this a’ units of electricity at the plant where massive pollution control devices operate to ensure that the gases released into the atmosphere comply with applicable standards.

Now the electrical power is transferred to the charging station mostly from the power plant far away where fossil fuels are burnt to generate it. (Green Energy does not use fossil fuels but it is presently a miniscule % of total power produced.) Now the EV is billed for the in-going electricity metered at the charging station and, say, consumes ‘a’ units so transferred to its battery per km. The corresponding power produced at the generating plant is a’ (a’>a, but close because of transmission and conversion losses). The fuel consumption and gaseous pollution per km will correspond to this a’ units of electricity at the plant where massive pollution control devices operate to ensure that the gases released into the atmosphere comply with applicable standards.

(Note that no standards apply to cooking at home – at present! A fuel gas burns completely leaving no solid residue (ash) nor products of incomplete burning like carbon monoxide and smoke or soot. Hence cooking with gas in rural households reduces pollution significantly. It is still not completely green; that will happen when cooking heat will come from electricity produced from renewable sources – a desirable but distant scenario.)

In contrast, the conventional car (in the company of thousands of others) consumes a shade more fuel and hence releases more gases per km because it cannot have elaborate efficiency-enhancers that a large, stationary power plant can have. In other words, despite the elaborate ‘power plant to charging station to car battery to actual conversion of electrical energy to car motion’ charade, the environmental load in this case is modest. And it would be stationary and away from human habitation unlike the moving polluter right in the thick of populations. Bottomline: The effective pollution potential of an EV is less than that of a conventional car.

Thus the pollution cost of running a petrol or diesel driven vehicle is marginally reduced on ‘per car’ basis and relegated to a faraway place, when it becomes electric! But the cumulative correction on ‘community of cars basis’ is significant. The ultimate triumph, of course, will be when the green power derived from renewable sources will charge and run the vehicles. Vehicles run on Green Hydrogen Fuel Cells which require charging of green hydrogen (produced from renewable energy by electrolysis of water) gas into the vehicle, already a reality, are also an example of this. The only thing they produce is water!

The process of making rabadi: This product results from concentration of milk by evaporation of water – a ‘diluent’ – using heat. The direct implications are: (i) This is different from making a porridge/kheer/firni where the focus is on ‘cooking’ something in milk. Here, a lot of heat released by burning of a fossil gas and resulting generation of greenhouse gases is consumed in evaporating water. We will take up the important nuances of this distinction a few posts down the line. (ii) The burning heats up the immediate environment – in this case, the kitchen – and reduces the proportion of oxygen in it making it feel stuffy. (iii) The accumulation of ‘green-house gases’ in the upper atmosphere is already devastating large swathes of land-masses thru climate disasters. (iv) Hence any reduction in the fuel consumption (and flue gas generation) would be welcome even with a slight increase in monetary costs – a lot like EV’s.

We can treat rabadi-making as boiling a predetermined amount of milk in a vessel over a gas-burning flame. When requisite amount of water has evaporated (and the volume reduced), sugar, flavourings and nuts are added and boiling continued for a few minutes to homogenize the dish. When milk powder is used, any proportions of milk and powder can be used to reach the same final dish.

We can treat rabadi-making as boiling a predetermined amount of milk in a vessel over a gas-burning flame. When requisite amount of water has evaporated (and the volume reduced), sugar, flavourings and nuts are added and boiling continued for a few minutes to homogenize the dish. When milk powder is used, any proportions of milk and powder can be used to reach the same final dish.

(A practical tip: The smartest way of using milk powder – not detailed by the powder marketer – is to prepare a paste or a slurry with cold milk and strain it thru the tea-strainer into the boiling milk with finger-rubbing the bottom of the strainer continuously. Finish by passing a spoonful of pure milk thru the same strainer in the same way to push in all the enmeshed material. Tap the inverted strainer lightly on the rim of the vessel to complete the transfer.)

Valid assumptions and the basis of comparison: (i) 1 litre of milk = 1 kg of milk. (ii) Milk has 85% water i.e. 15% milk fat + non-fat solids. (iii) Milk powder has no moisture i.e. is bone-dry. (iv) The end product has the same composition in either case. Sugar, garnishing nuts and flavouring remain common in both the cases. (iv) Milk-milk powder equivalence: 6.67 to 1. (v) In the ‘milk + powder’ case, 40% milk replaced with milk powder.

Basic calculation: Water to be evaporated: 425 gm. for milk-only method and 85 gm. in the other. Quantity of product expected: (575 g. of milk constituents) + water + sugar + flavourings + nuts etc. Note that the volume will have shrunk i.e. product will be denser.

Method 1: Without using milk powder

Ingredients: 1 lit milk, sugar, flavouring spices, nuts etc.

Other inputs: Cooking gas (x units), cooking time (y units), inconvenience (z units). Pollution potential corresponding to evaporating 425 gm. water from a concentrating mixture at home, say p units.

Method 2: With milk powder

Ingredients: 0.6 lit milk, 60 g. milk powder, sugar, nuts, flavourings etc.

Other inputs: Cooking gas (x’ units), cooking time (y’ units), inconvenience (z’ units). Pollution potential: Corresponding to evaporation of 85 g. water from a mixture that has concentrated less than in the first method + pollution at the industrial plant which made 60 g. milk powder, say, p’ units. (p > p’)

Indicative comparison of costs:

(i)Monetary, time and effort cost: The comparision is between cost of [( 1 lit milk + ingredients) + x + y + z] and the cost of [(0.6 lit milk + 60 g. milk powder + ingredients) + x’ + y’ + z’]. Here, cost of 60 g. milk powder > 0.4 lit milk and x > x’, y > y’, z > z’.

The difference (cost of 60 g. powder – cost of 0.4 lit milk) is dampened by the aforesaid efficiencies of large scale industrial production and hence ‘milk cost’ in the second case is not significantly higher. The ‘non-milk cost’ difference i.e. [cost of (a + b + c) – cost of (a’ + b’ + c’)] is positive i.e. lower in the second case. If you value your time and effort, this difference can totally nullify the ‘milk cost’ difference thus making the second method quite attractive.

(ii) Pollution cost: The difference (p – p’) would be a very real contribution to the environment. Precisely this kind of attitude will save us from climate disasters because millions of such microscopic contributions can be scattered all over the world and make a difference on a large scale.

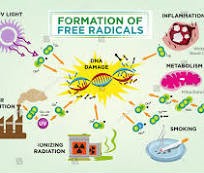

Complex considerations of nutrition loss: Evaporating large amounts of water in an open pot at home means that the temperature of evaporation goes on increasing and some loss of nutrients and quality of protein is inevitable. Moreover, the ‘atmosphere’ containing oxygen is in direct contact with the evaporating milk. Initially, when water vapour flux is high, air is largely pushed away or its partial pressure in the atmosphere in contact with the milk is low. But as vapour inevitably thins out towards the end, the all-pervasive oxygen does hug the milk surface in the pot more closely causing some nominal ‘burning’.

Such ‘oxidatively abused’ food is bad for health in ways that are not fully understood but it is clear that such oxidized components act as oxygen carriers in our body and oxidize other constituents. (Such oxidation is significantly lower in making milk powder because of lower temperatures of evaporation and almost complete absence of oxygen because of vacuum). For example, oxidation of the ldl-cholesterol in the arterial walls is believed to trigger the formation of a plaque that can block blood flow.

Such ‘oxidatively abused’ food is bad for health in ways that are not fully understood but it is clear that such oxidized components act as oxygen carriers in our body and oxidize other constituents. (Such oxidation is significantly lower in making milk powder because of lower temperatures of evaporation and almost complete absence of oxygen because of vacuum). For example, oxidation of the ldl-cholesterol in the arterial walls is believed to trigger the formation of a plaque that can block blood flow.

Oxidative free radical reactions are considered prime reasons for onset of cancers. Dietary antioxidants are expected to partly nullify such pathogenic oxidation but then ensuring a preventively high antioxidant levels is dicey. Using milk powder reduces the ‘corrective’ load on dietary antioxidants.

Oxidative free radical reactions are considered prime reasons for onset of cancers. Dietary antioxidants are expected to partly nullify such pathogenic oxidation but then ensuring a preventively high antioxidant levels is dicey. Using milk powder reduces the ‘corrective’ load on dietary antioxidants.

Conclusion: Thus using milk powder in domestic cooking is monetarily a shade more expensive but more convenient, time-saving, less polluting and more nutritive. Take your decision. But remember: here it works because prolonged, inefficient heating with fossil fuels (which is mandated by the need for evaporation of a lot of water) is involved. Obviously, do not make milk for drinking out of milk powder!

Next post: Indian consumer and processed foods

Diversity meets diversity!

(Visit ‘disclaimer’)

7 thoughts on “Cost-benefit analysis of cooking with milk powder: Introducing the environmental cost of food processing”

Thank you a lot for sharing this with all folks you really know what you’re talking about! Bookmarked. Kindly also consult with my web site =). We may have a link exchange contract among us!

Thank you for the kind words, but we are not looking for a link exchange contract. Do keep visiting our website if it adds value to your food and life.

Your articles are extremely helpful to me. Please provide more information!

Thank you for your post. I really enjoyed reading it, especially because it addressed my issue. It helped me a lot and I hope it will also help others.

The articles you write help me a lot and I like the topic

Can you write more about it? Your articles are always helpful to me. Thank you!

What more would you like to know on the topic? Kindly specify here. Also, feel free to browse our blog for more details provided in related posts.